Scale power has domestic leading modern production base

Yingkou sounrun new material engineering technology co.,ltd.Covers an area of about 140,000 square meters of modern production plants, monomer workshop area of 65,000

square

A national high-tech enterprise, senior representative

At present,Yingkou sounrun new material engineering technology co.,ltd. has become the industry's most influential and professionalism of senior representatives of the unit. Since its inception, Yingkou, like repeated AP industries and local standards.In 2013, the company through the national high-tech enterprise. Books compiled by company «phenolic foam production • design • construction» published in 2 01 3 years formal and public offering.

Capacity strengths a world-class imported equipment, production capacity ranks first in the country

Research-professional technology combined with leading-edge information, leading the industry development

Professional SOUNRUN

Professional technical development:

Professional production line:

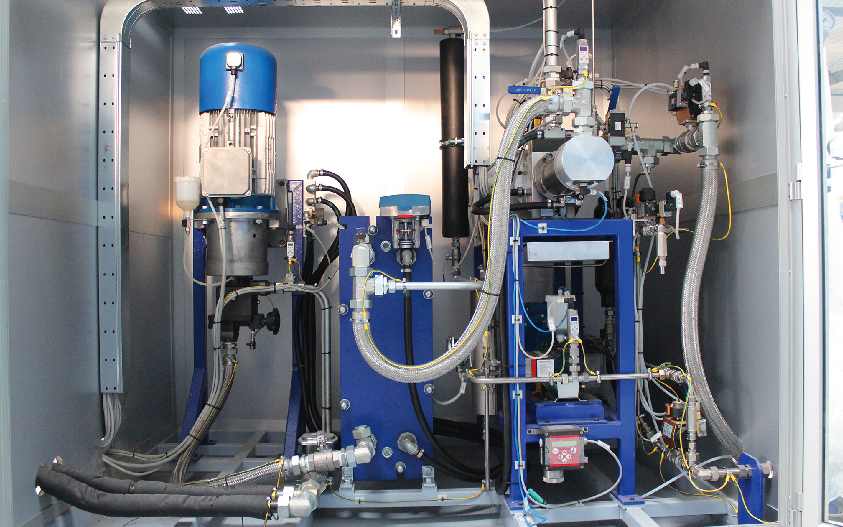

Company introduce 5 Italy Ou Musi (OMS) phenolic foam insulation board industrial lines, equipment level of world class.1. the OMS line of computer intelligent control, automatic mode, every aspect of the production control can maintain a high accuracy, effectively guaranteeing the high quality and high stability of the output panel.

2. Advanced 30 metres of laminating machines, effective control of line speed, ensure that the output sheet foam evenly, completely, high close rate determines its low thermal conductivity, tensile strength and high strength.

3. automatic trimming and cutting technology, strictly control the dimensional uniform stable and smooth.

Professional business management systems:

Company has a comprehensive research and development system, quality management system, production system and marketing system and perfect after-sales service system. Xia 14 functional departments within

the company, employs more than 200 people. Scientific management, strict regime ensured the steady

development of enterprises.

Quality sounrun

In sounrun,Quality is a sublime belief circles!

"Depending on the credibility of the enterprise life, depending on the quality of dignity of the enterprise!" Is everyone stuck to the spirit of the idea. Quality is our dignity, "is everyone the same Supreme belief.Full range ensure product quality:

Independent constant temperature material: phenolic resin storage requires high temperatures, usually in the 10-20 constant temperature storage can effectively guarantee performance stability.

Precision manufacturing process control:

Mixing reactor material all take place through electronic measurement, measuring well pressure pump from the pipe through to the workshop, the production extruder head through automated mass flow meter, in accordance with a fixed value per unit of time stable extrusion and production adjustments timely and effective, and fully guarantee the material accurately, ensure product quality stability.Adequate curing period:

I have 1. 50,000 square metres of aging workshop, product ageing period 2 1 day. After sufficient curing period, the more stable product performance, size, avoids the plate due to the curing is not completely warped, thermal cracking or even fall off, and so on.

Strict inspection system:

My company will be higher than the industry standard of enterprise standard as a basis for product testing; Every batch must undergo a rigorous factory testing, the indexes of ensures that all products meet high standards and high quality.

Fault sounrun

Product liability 13 one, comprehensive product quality

Every product from the ratio of raw materials, production of processed products to aging, packaging, storage, until the factoryTransportation after every procedure Trinity one by one, each link has the most advanced device support, most professional technical support as well as strict management system, and full control.

External thermal insulation system on the customer's responsibility to provide comprehensive solutions

Pre-sales product inspection, ensuring high quality sale detailed explanations, targeted to tailor optimal programme; after sales project tracking, construction technology to give the low-down, technical guidance on construction site one by one company to provide customers with full and thoughtful, comprehensive, high quality range of services. Company according to different customers and different regional characteristics of external thermal insulation systems integrated solutions tailored to customer, so that every customer experience with the company saves time and effort, good ease of service.So far, the company has more than 20 million square meters of construction performance, typically hundreds of cases, customers praise, with many power companies to establish a

long-term and stable cooperative relations.

Responsibility for staff-work together to staff to promote the growth of the enterprise's development

Talent, pay attention to the reserve and training, humane management systems, scientific and reasonable division of labour and improve the compensation system, generous

benefits, the company has always been in good faith to everyone, put the needs of employees at the top of a rational allocation of resources.

Social responsibility-responsibility to social harmony and spreading warmth into thousands of families

For a long time, the company strictly in accordance with high standards and high quality requirements, innovative technology, independent research and development to produce

high quality, environmental protection and pollution-free modification of phenolic foam thermal insulation materials for building purposes. Accelerate the achievement of the national

"housing industry" production goals, improve manufacturing productivity, improves the overall quality of housing, an increase in service life and reduce labor and construction costs,

reduce material consumption, and avoids the building and site, environmental pollution, achieve real energy saving and environmental protection.

_4g8g.png)

_gezj.png)